Collective protection

Self-supporting guardrails and translucent nets

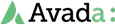

Self-supporting railings

Self-supporting railings ensure safety on terraces when fixation on a parapet or concrete slab is not possible (avoiding any ceiling drilling work, preserving the roof’s waterproofing

Collective protection against falls from height

Its installation is mandatory in certain circumstances, according to Law 31/95, the Occupational Risk Prevention Law, which states that collective protection systems such as railings will be prioritized over individual ones.

Easy assembly, lightweight, and robust

They are one of the preferred means to protect workers because they do not require their active involvement, specialized training, extensive maintenance, or additional equipment. They are easy to assemble, lightweight yet sturdy.

Designed to be easily installed on most existing support structures

Handrails, supports, and aluminum arrangement profiles

Concrete

counterweights encapsulated in plastic.

Connection

accessories: sleeves and end caps

All aluminum railings are available in three finishes: raw aluminum, powder-coated, or anodized.

For the assembly of the railings, it is necessary to follow the provided assembly instructions. The safety railing adapts to all terrace configurations thanks to its set of connection accessories.

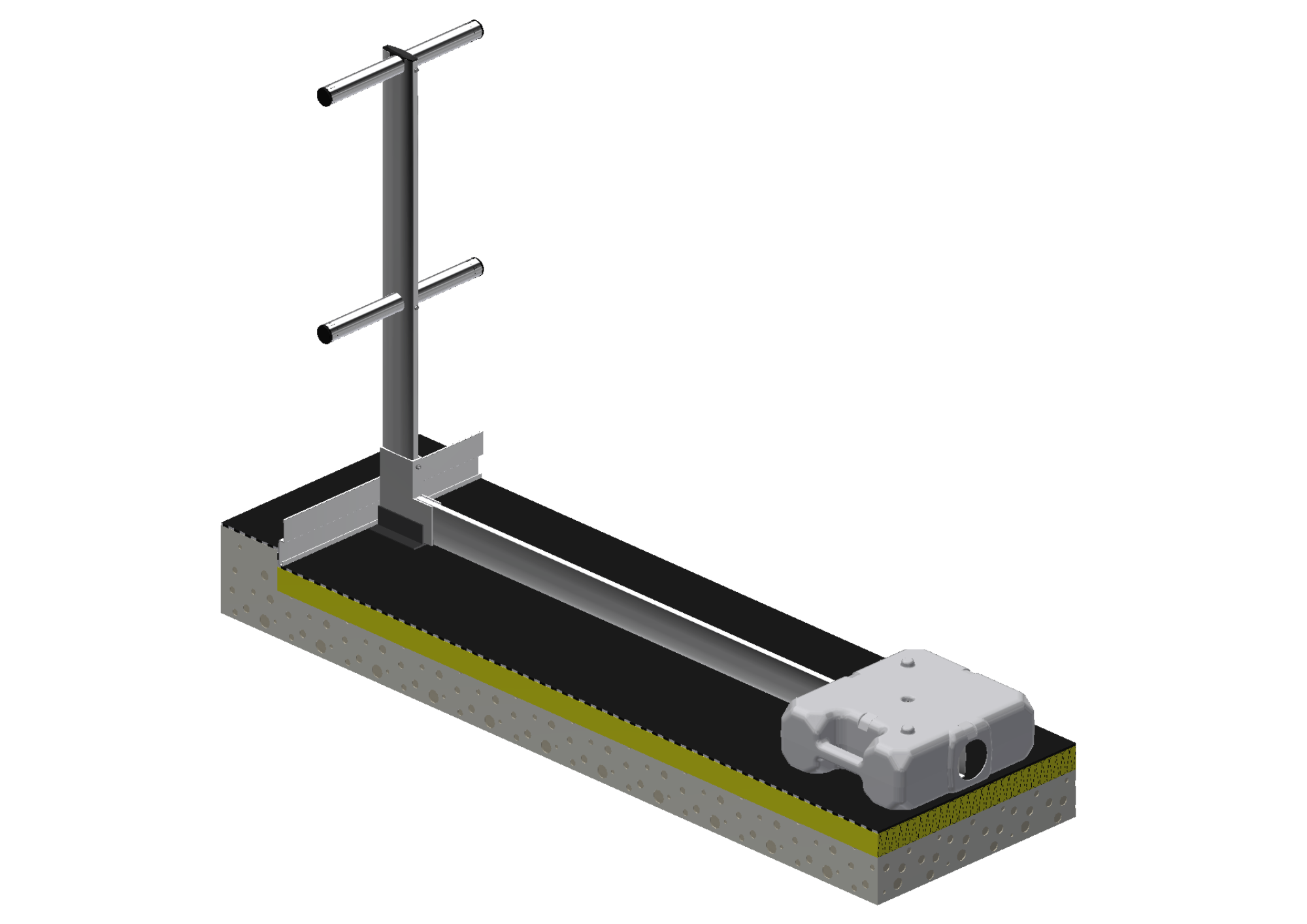

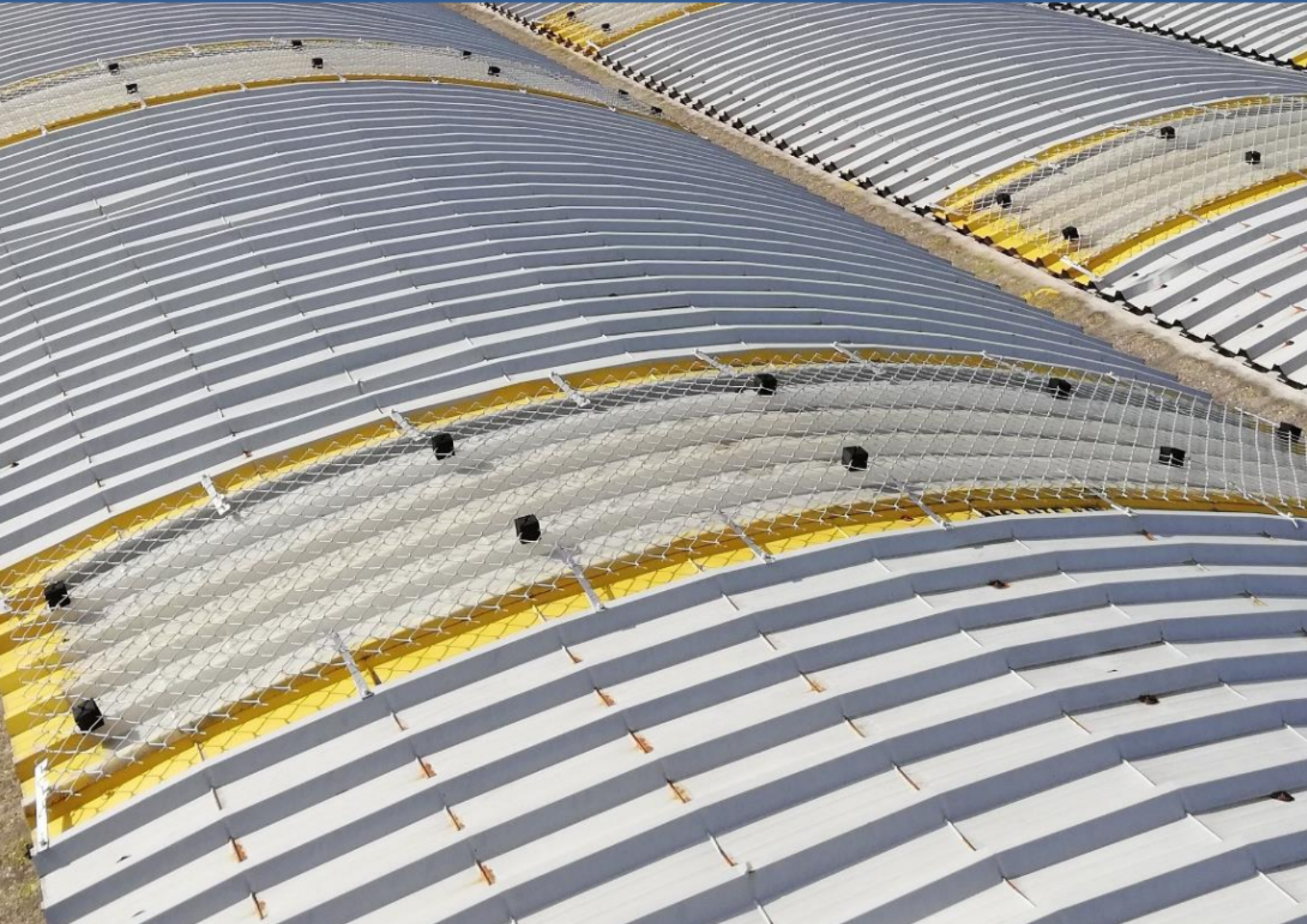

Protection with translucent nets

The protection net for translucent materials has been designed for corrugated sheet roofs and sandwich panel roofs with translucent panels to provide a safe, cost-effective, and easy-to-install solution.

Constructed with a simple galvanized steel mesh

The device is made up of a 2.1 mm galvanized steel twisted mesh, forming diamonds of 50 x 50 mm, and is available in widths of 1000, 1200, 1500, 2000, 2500, 3000 mm, and lengths of up to 25 m.

Fixed directly onto the translucent panel.

The mesh is attached to the translucent panel, directly onto the corrugations of the profiled sheet (minimum thickness 0.5 mm), using self-drilling screws equipped with sealing washers.

The system has been tested, successfully meeting all the required criteria

The mesh complies with the GIF test protocol, ‘March 1997 Protocol for protection of translucent panels,’ and meets the 1200 Joules impact resistance test.

The system has been tested according to the UNE-EN 15057:2007 and UNE-EN 1873:2015 standards, undergoing impacts of 600J and 1200J respectively, successfully surpassing all required criteria